SHREDLAGE® harvest recommendations

The chopped material produced by the SHREDLAGE® processor is characterized by the following attributes:

- Chop length of 21-30 mm

- 95% of the stalk content thinner than 4mm

- Peeled stalks

- Flexible pieces

- Kernels split into four or eight pieces

Freshly chopped material

Fermented chopped material

The recommendations for SHREDLAGE® harvesting are essentially the same as those for conventional corn silage. Experience has shown that particular attention needs to be paid to the stalks, as their degree of conditioning diminishes at an earlier stage than that of the kernels.

The recommended dry matter content is in the range from 32-36% DM. More moist crops, below 32% DM, can lead to increased effluent formation while DM levels above 36% have to be compressed with particular care.

The following recommendations serve as guidelines for correct machine configuration.

Chop length (mm) | Fresh mass | Dry matter |

| 30 | 70 | 30 |

| 26 | 65 | 35 |

| 21 | 60 | 40 |

The roller gap must always be set to deliver the desired degree of crop conditioning and kernel processing.

Continuous monitoring of the conditioning quality and, if necessary, adjustment of the machine settings in accordance with the criteria mentioned here is essential.

(Brown midrib (BMR) corn varieties might required a roller gap setting some 0.5 mm narrower than what is usually recommended for corn due to the sponginess of the BMR stalks.)

The following methods for checking the processor settings are available:

SHREDLAGE® testing methods:

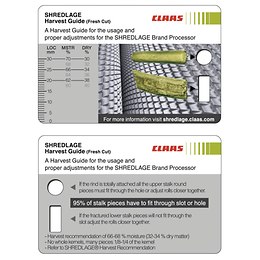

- SHREDLAGE® test card which can be used to determine the length and thickness of the particles.

- 1-liter sample cup for a "quick test" of the kernel processing. All the kernels in the sample should be divided into at least four parts, eight being ideal, and there should be no unprocessed kernels.

- Corn Silage Processing Score CSPS, degree of kernel processing. CSPS is a laboratory analysis method which relates the degree of processing of the kernels to the total starch content of the sample. This score depends on a number of different parameters. Along with the dry matter content, the variety and the characteristics of the location, the configuration of the machine and the level of wear of the cracker rollers obviously also play an important role. In the case of SHREDLAGE®, the CSPS of fresh corn should be greater than 70.

- The Penn State shaker box is designed to be used at the clamp in order to check the SHREDLAGE® processing. Different-sized sieves are used to separate and quantify the fractions of different-sized material. The goal is to obtain a distribution of 25% for the top sieve and more than 40% for the middle sieve.